JS Series Multipurpose SCARA Robot

The JS and JSTH Series have a wide variety of models with the arm length ranging from 250mm to 1,000mm. The JS Series has a double shaft, and the JSTH Series a single shaft. A variety of models also include cleanroom specification (class 10) models in the JS Series, and long Z-axis stroke models (300mm/500mm) in the JSTH Series. (The standard stroke is 200mm.) With the easy-to-use Janome’s original system software common to all Janome robots, along with their high accuracy, high speed, and wide work area, the JS and JSTH Series can help you automate your production site, improving productivity and product quality

Features

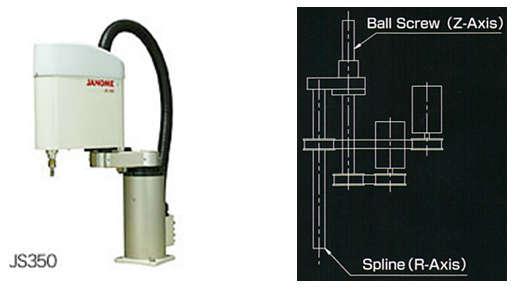

Double Shaft SCARA JS Series

High trajectory accuracy achieved by the separately-controlled Z- and R-axis motors make the JS Series the right choice for precision CP (continuous path) operations.

Clean Room Type Models with Clean Class 10 (0.3μm)* Specifications

1. The special airtight structure and vacuuming system minimize dust inside the robot.

2. Special external conductive coating prevents static electricity.

3. Low-dust grease is used for the Z-axis spline and ball screw; also, the Z-axis is covered by a special anti-static accordion hose.

4.The robot (not including the control box) can be used in both the clean room and regular environments.

What is Clean Class 10?

Clean Class 10 is defined by Federal Standard 209D as a particulate count that shall not exceed a total of 10 particles of a size of 0.5μm or greater per cubic foot of air.

Single Shaft SCARA JSTH Series

All connecting cables, such as those for soldering devices, can be bundled together in the hollow Z-axis shaft for a more organized workspace.

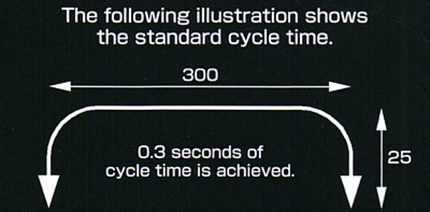

High Speed & High Precision

The combination of the high-powered AC servomotor and Janome’s original highly rigid mechanism delivers top-class standard cycle time. The repeatability of ±0.01mm ensures high.

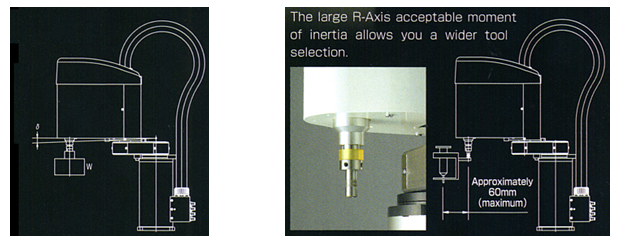

Powerful & Highly Rigid Arms

The highly rigid arms can carry a work piece of up to 20kg. The deflection amount (shown as δ in the image on the right) of when carrying a work piece of 4kg with the fully extended arms is only 0.04mm. The maximum acceptable moment of inertia of the R-axis is 0.1kgm2, which allows you to handle heavy loads and gives you a wider selection of tools.

User-Friendly Tool Piping

The robot comes equipped with14 signal wires and 4 air tubes. The internal piping system allows you to create compact piping and wiring layouts.

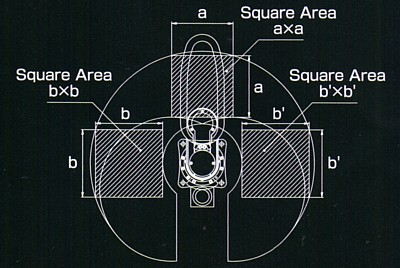

Wide Square Area for CP Movement

The wide square areas of 210mm x 210mm (b x b righty and b’ x b’ lefty) are ensured for the JS350.

Large and Clear View Teaching Pendant (Optional)

The teaching pendant has a large, easy-to-see LCD screen. The display language can easily be switched between English, German, Italian, Spanish, French, Korean, Chinese, and Japanese. The coordinate values can be displayed in millimeters or inches.

Simple, Easy-to-Use Operation Box (Optional)

The optional operation box equipped with the start switch, program change switch, and emergency stop switch is available.

More Information

1. Software